Quality is our Culture

Safety, Quality, and Consistency

At Somic America, quality assurance is not just a process; it’s a pledge to safety and reliability. With our IATF 16949 certification, we set the bar high for every component we produce, aiming for zero defects and 100% on-time delivery. Our approach integrates meticulous planning, rigorous testing, and continuous feedback loops across teams, ensuring that from the drawing board to the road, every product reflects our unwavering commitment to quality.

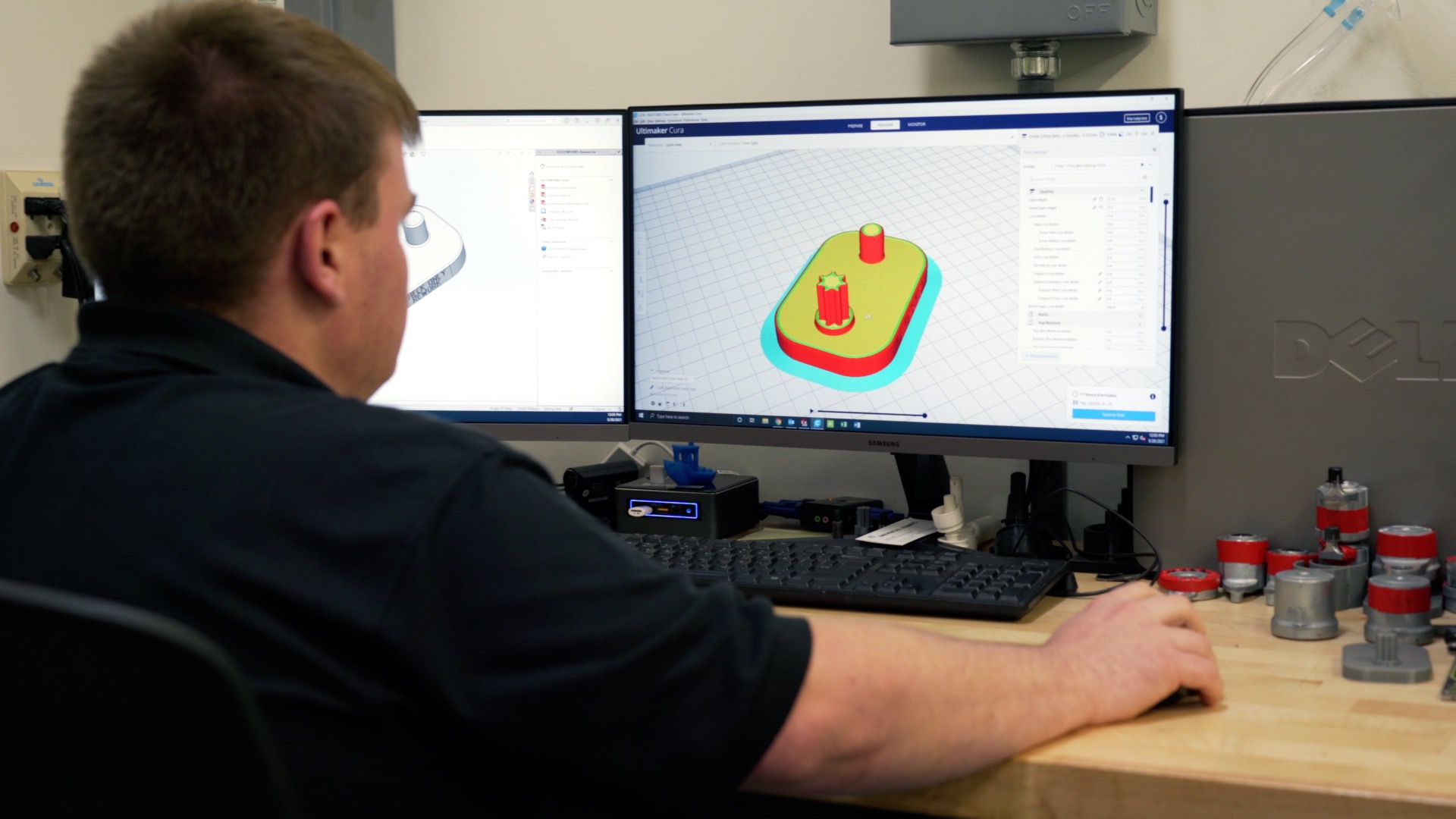

Standardized Work

Standardized work is the heart and soul of quality. At the beginning of the process, the engineering team, machining team, and quality team collaborate to determine the standardized work for producing each component. When standardized work is implemented well, everything else is a matter of validation and verification.

Attention To Detail

Issues as small as dust getting in a ball joint, or inconsistent plating can have fatal implications. For that reason, Somic’s dedication to detail is unmatched. We make over a million components each week. Every single one is tracked through its product journey, and the smallest imperfections are caught, remedied, and assessed to prevent future imperfections.

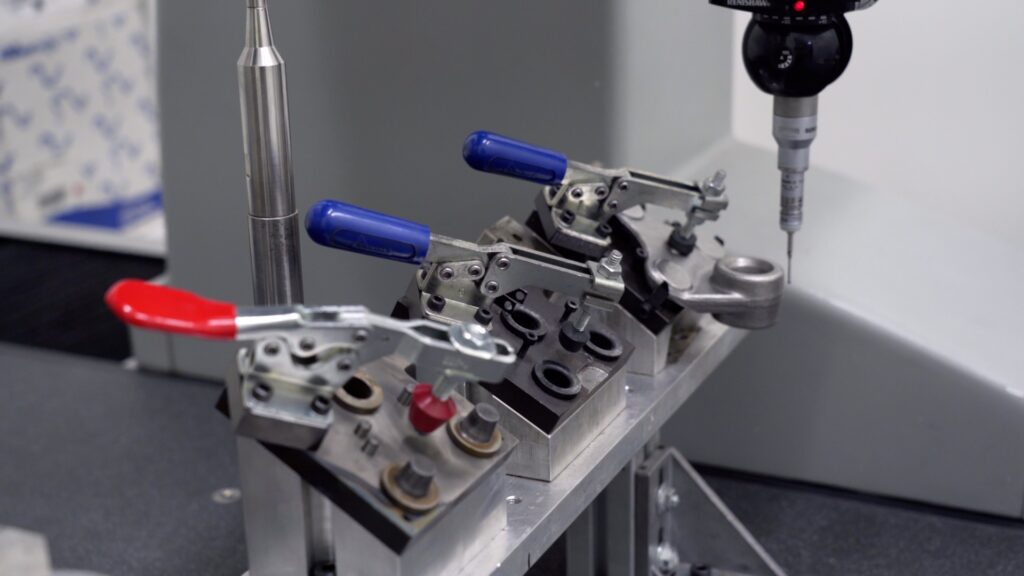

Validation

Detailed quality checks are built into our standardized work every step of the way. After machine operators handle each component and conduct consistent assessments, robots scan for imperfections, and finally a team of quality staff inspect each part before it leaves our doors. This product validation process ensures that we are meeting our 100% quality commitment.

Culture Of Quality

Beyond an insistence upon product perfection, Somic’s positive, open culture fosters an environment where every tiny issue is addressed.

Engineers and quality technicians rely on machine operators as the team members with eyes and ears on our products 24 hours a day. In fact, Somic lives its mission of continuous improvement, Kaizen 改善, so wholeheartedly, that staff are encouraged to recommend ways to improve efficiency, quality, and safety. 90% of Somic’s Kaizen initiatives were suggested by machine operators!

By truly listening to each other, and constantly striving for perfection, we deliver quality components every single time.